Co2 DHP Systems

DHP – DIRECT HIGH PRESSURE – Co2 CLEAN AGENT FIRE SUPPRESSION SYSTEM UNIT

PRODUCT OVERVIEW & PRINCIPLE OF OPERATION

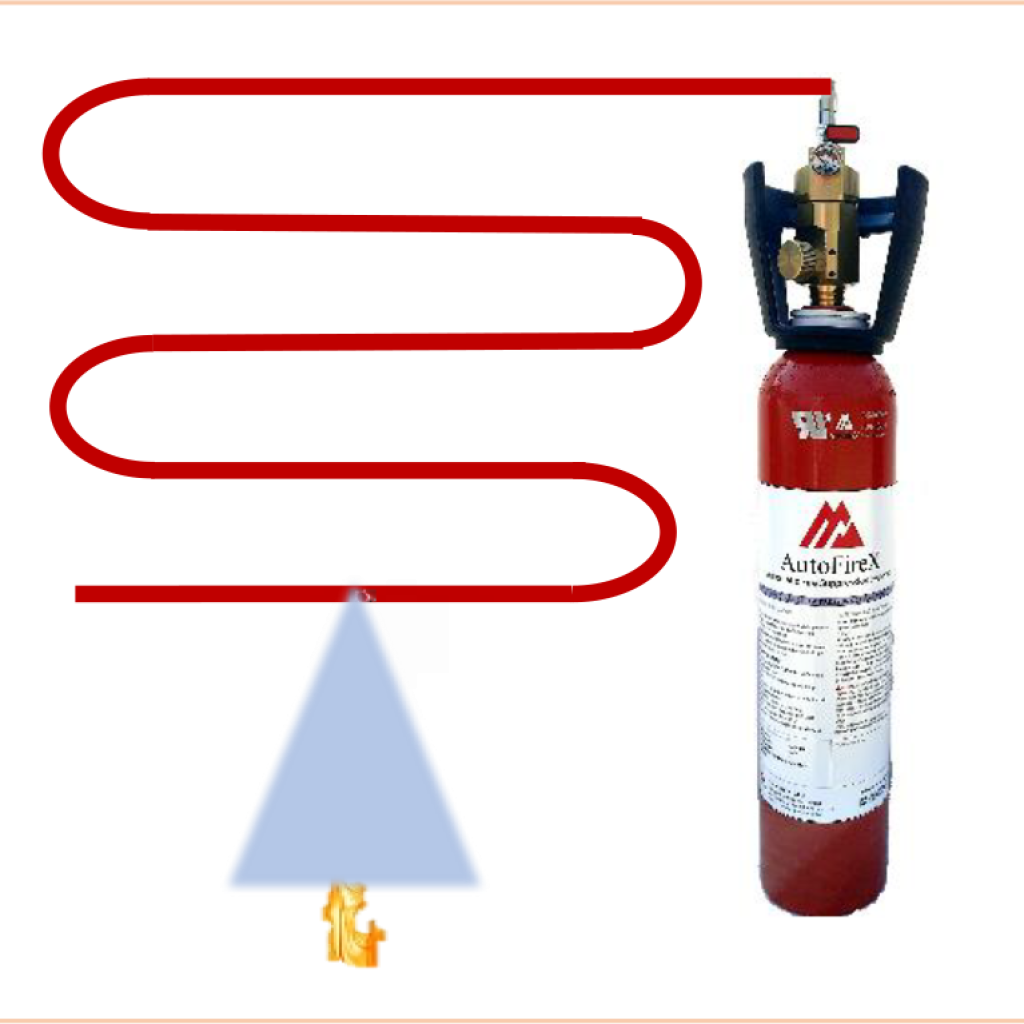

AutoFireX® DHP- Direct High-Pressure Co2 Systems are primarily a PreEngineered Automatic Fire detection and suppression System utilising High pressure agent Co2. These Units are designed, manufactured, and

tested in ISO 9001:2015 certified facilities

The AutoFireX® Linear Pneumatic Fire Detection Tubing (FDT) is installed and connected to DHP Valve and routed throughout the protected hazard area/enclosure. Being heat sensitive, the primary function of Linear

Pneumatic Fire Detection Tube (under pressure) is to detect heat/fire and activate the valve for discharge of the agent by rupturing at the hottest point along its installed length on flame impingement. On rupture a nozzle is formed at the burst point.

The Co2 clean agent under pressure, in the cylinder then flows out through the burst point, distributing the Co2 gas through the protected

enclosure and extinguishing the fire instantly.

Each DHP system consists of a High-Grade Brass Direct valve assembly with 3 Ports (1 x Inlet connection-W28.8×1/14″- 1 1/8″-12 UNF-2A, M 25x 2; 1 x Outlet connection M10x0,75 & 1 x Filling connection- W 21,8 x 1/14″) and siphon tube, a quarter turn Next Gen isolation valve with a G 1/8” threaded push-in/ slip on union is provided to connect the AutoFireX® Fire Detection Tubing. A Pressure gauge is also be provided to monitor the system pressure. The system is supplied complete with light weight UL approved High-Pressure Seam less Aluminium Alloy Cylinders and Brackets and DHP valve Guard.

To assist in annunciation, an optional pressure switch can be installed at the end of the detection line using an End of Line Adaptor, also available with the system. The pressure switch provides a potential free contact, that can be interfaced, with existing FACP (Fire Alarm Control Panel) to indicate system discharge, shutdown ventilation, shut-off electrical power, as may be required. Alternatively, it can also be connected to a Audio Visual (A/V) alarm unit for annunciation.

Since the units are supplied as automatic units no simultaneous manual or electric actuators are provided

GENERAL SPECIFICATION

| SYSTEM INFORMATION | PERFORMANCE INFORMATION | ||

| PRODUCT CODE | AGENT QTY. | OPERATING PRESSURE(@21oC) | MAX PROTECTEDVOLUME @ 34% Design concentration |

| 6000102 | 2 kg | 57 Bar | Up to 1.98m3 |

| 6000105 | 4.5 kg | 57 Bar | Up to 3.96m3 |

| 6000107 | 6.5 kg | 57 Bar | Up to 6.54m3 |

| 6000109 | 9.0 kg | 57 Bar | Up to 8.49m3 |

*Figures based on ideal conditions in fully enclosed space. Actual figures may vary according to application.

Maximum volume coverage is determined by agent concentration discharged within the enclosure where the fire hazard is located. The discharge time for DHP system utilising various agents differ from agent to agent and capacity of the cylinder.

For details write to: info@autofirex.co.uk

AutoFireX® Co2 DHP AutomaticFire Suppression Systems Advantages

- DHP/IHP Co2 Fire Suppression Systems with major UL Recognized Components

- Reliable,24 x7 Automatic Fire Detection & Protection for machines, equipment, and data against Fires.

- Fast-Detection & Suppression of fire within seconds, reducing equipment damage and downtime

- Utilizing Multiple Detection points-ULRecognized Component AutoFireX® Fire Detection Tube (FDT)which is a Linear Pneumatic Heat detector that can detect fire throughout its installed length

- Intrinsically safe for electric charged areas. No External Power required to activate the system.

- No “False Alarm” or Discharges as systems only activate in the event of an actual fire/heat impingement.

- Post Discharge – Systems utilizing clean suppression agents require no post-discharge clean up.

- Easy to install in any new or existing Equipment’s (Electrical Panels, server rack etc.).

- Environmentally Friendly systems utilizing UL certified seamless cylinders and Clean Agents, not harmful to equipment or the environment.

- Interface Options -Systems comes with various options to initiate activities like Annunciation, shut on or shut of Power supply, ventilation, interface and monitoring through BMS, SCADA etc.

- Low Maintenance-AutoFireX systems do not interfere with installation or maintenance of equipment and can also be retrofitted to existing equipment’s.

- Cost Effective Service-can be quickly and cost effectively serviced and recharged after a fire

SUITABLE APPLICATIONS

APPLICATION SPECIFIC DESIGNED PRE -ENGINEERED AUTOMATIC FIRE SUPPRESSION SYSTEMS FOR CRITICAL ASSESTS & EQUIPMENTS PROTECTION IN ALMOST ALLVERTICALS

ELECTRICAL CABINETS & SERVER RACKS

LT & HT Switchgear Panels, Capacitor Panels, Server racks in Data Centres, PLC & process automation control cabinets; critical data processing equipment; UPS cabinets; medical equipment; switchgears,

HVAC Panels, Escalator Panels, Telecom towers

AIRPORTS

METRO RAIL

TELECOM

IT DATA CENTERS

CNC /EDM MACHINES, FUME HOODS

Enclosed automated milling machines; EDM machines; robotic welding machines; plastic injection moulding machines, Fume Hoods, Walking fume hoods,

AUTOMOTIVE

OIL & GAS

MANUFACTURING & PROCESS APPLICATIONS

Dust & mist collectors, Paint booth, Process Control Cabinets, Chemical storage areas, DG Sets, Engine & Motor bays, Gas Turbines, Electrical Transformers, Dust Extractors, Filtration Plants.

PHARMACEUTICAL

INDUSTRIES

MFG. PLANTS

MINING MACHINES & MOBILITY VEHICLES

HEM Vehicles (Engines & Motor bays, Hydraulics, emergency brake, etc.) Control panels for Excavators, Drag Lines, Dump Trucks, Loaders, Dozers, Drill Rigs, surface miners, critical U/G Mining equipment’s

MINING

MARINE

PORTS CONTAINER DEPOT

POWER GENERATION & TRANSMISSION

Wind Turbines, Solar Energy Farms, Energy Storage Systems, Cable Trays & Cable Tunnels, UPS Battery Racks, Electric Vehicle Charging Units.

POWER

RENEWABLE ENERGY